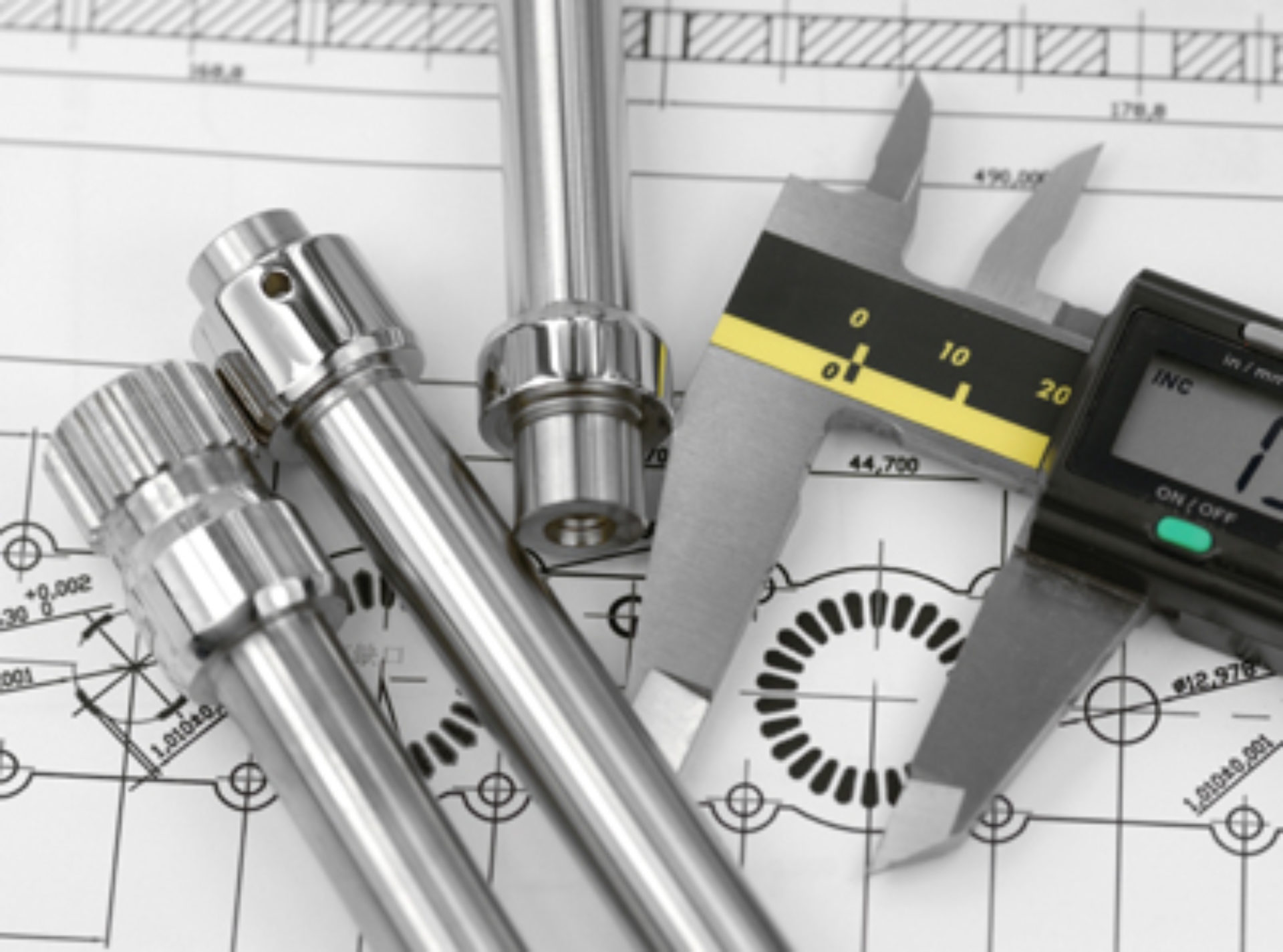

Medical Device and Pharmaceutical Manufacturing along with most manufacturing regulated Industries require Metrology, Quality and Engineering. Metrology, Quality and Engineering is our expertise. We understand the world of cGMP, c GLP and cGDP and we excel in it. With close attention to detail we make sure all Test procedures coincide and can be cross referenced with Manufacturing procedures. We plot each data point for each test to deliver a full range calibration or test and to deliver the highest quality results. Our reporting is clear and concise and surpasses the Industry standard.

Metrology is the science of measurement.[1] It establishes a common understanding and defines units being measured in a Manufacturing Facility. It also defines the applied measured units and calibration accuracy tolerance for each instrument being used in a Manufacturing Facility. Calibration’s should be performed using a 4:1 ratio Standard: Unit Under Test comparison method while using N.I.S.T. traceable Standard to ensure quality.

Metrology is divided into three basic overlapping activities.[6][7] The first being the definition of units of measurement, second the realization of these units of measurement in practice, and last traceability, which is linking measurements made in practice to the reference standards. These overlapping activities are used in varying degrees by the three basic sub-fields of Metrology.[6] The sub-fields are scientific or fundamental metrology, which is concerned with the establishment of units of measurement, Applied, technical or industrial metrology, the application of measurement to manufacturing and other processes in society, and Legal metrology, which covers the regulation and statutory requirements for measuring instruments and the methods of measurement.

In each country, a national measurement system (NMS) exists as a network of laboratories, calibration facilities and accreditation bodies which implement and maintain its metrology infrastructure.[8][9] The NMS affects how measurements are made in a country and their recognition by the international community, which has a wide-ranging impact in its society (including economics, energy, environment, health, manufacturing, industry and consumer confidence).[10][11] The effects of metrology on trade and economy are some of the easiest-observed societal impacts. To facilitate fair trade, there must be an agreed-upon system of measurement.[11]